How Polymer Sound Absorptive Barriers Are Transforming Noise Control

The problem of noise pollution has become one of the most incurable problems for all countries across the world. Whether you are moving across highways, urban or rural roads, you will find excessive noise pollution. To combat this problem, the role of acoustic or soundproof barriers cannot be ignored, but as most of these barriers reflect disruptive sounds in the other direction, they cannot provide a long-term solution. Unlike these barriers, the use of polymer sound absorptive barriers adopts an advanced approach by absorbing sound waves. These barriers not only improve acoustic comfort but also add functional and aesthetic value to the spaces where they are installed.

Why Choose Polymer Sound Absorptive Barriers?

1. Effective Noise Reduction

Unlike reflective barriers, absorptive barriers convert

sound energy into heat, thus providing a noticeable decline in noise levels.

This makes them particularly useful for areas that are prone to high traffic.

2. Attractive

Polymers can be converted into various designs, shapes, and

colours. As a result of this, these barriers can be easily converted according

to the environment suitable for the place where they are installed.

3. Durability and Weather Resistance

Polymer is capable of standing strongly in extremely harsh

environmental conditions. This makes them suitable for all types of atmosphere.

4. Improved Safety in Work Environments

The sound generated by heavy machines in industries can

create difficulty in clear communication. Polymer absorptive barriers help to

reduce disturbance during communication and create safer working conditions.

5. Eco-Friendly Options

Sustainability is another advantage of these barriers.

Certain polymers can be manufactured using recycled materials or have a smaller

carbon footprint compared to traditional barrier materials. This makes them an

environmentally responsible choice.

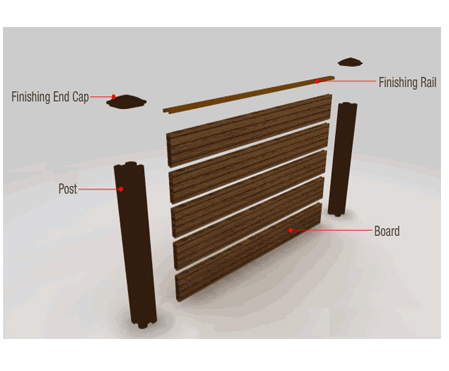

6. Ease of Installation

Due to the lightweight of polymers, it is easier to carry

and install these barriers easily without any hard endeavours. This not only

saves time but also makes them an effective solution for large construction

sites.

Materials Used in Developing Polymer Noise Barriers

Several types of polymers are used to create absorptive

barriers. Each of these materials is enriched with distinct benefits:

• Polyester

fibre: Capable of absorbing high-frequency sounds while remaining durable.

• Glass Fibre

Reinforced Concrete (GFRC): It has the combination of strength and versatility

in design.

• Geopolymers:

Made from industrial waste, they play a greater role towards sustainability

while absorbing noise.

• Natural

rubber: Performs well in absorbing low-frequency sounds and works effectively

as a binder in insulation panels.

Final Thoughts

Comments

Post a Comment

Please do not enter the spammy link!